A new direction in the work of our company is

upgrading and repair of compressors to provide the productivity not lower than in project and

increasing of the efficiency (1-1,5%) while reducing energy costs, increasing of number of

maintenance intervals and reliability.

Modernization

of equipment is carrying out on a production basis NE "Energomash" Co. Ltd., repairs - at the

customers. This scope of work is recommended to perform for compressors with significant

operating time. Upgrade provides the improvement of parameters of a compressor, and its stable

maintenance, and includes: changing the design of the rotor, replacement of diffusers and

diaphragms, constructive change of tubes in tube bundles of the terminal and intermediate

coolers, changing the gear ratio of the gear pairs to change the speed of the compressor, the

replacement of bearing shells.

Modernization of the turbo compressor units of K-250 type.

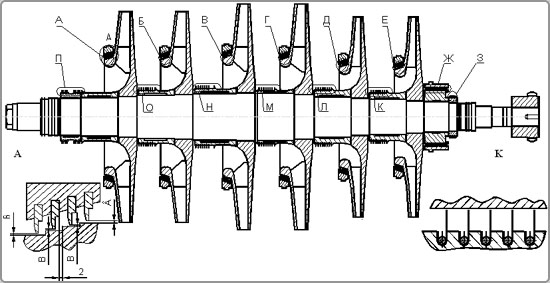

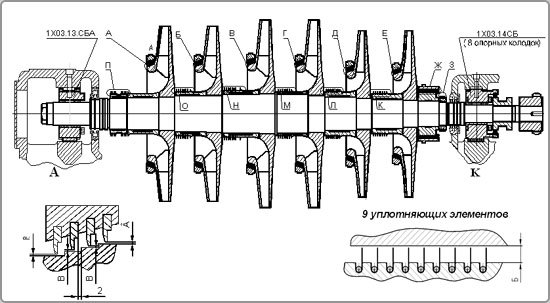

The rotor of centrifugal compressor of K-250 type before modernization

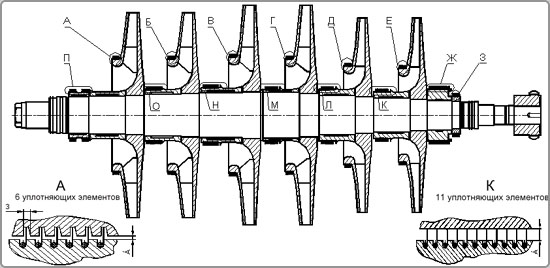

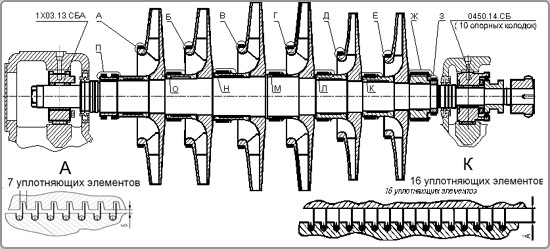

The rotor of centrifugal compressor of K-250 type after modernization

Modernization of the turbo compressor units of K-500 type.

The rotor of centrifugal compressor of K-500 type before modernization

The rotor of centrifugal compressor of K-500 type after modernization

Modernization of the compressor and auxiliary equipment includes:

- Changing the design of the rotor and the compressor housing;

- Replacement of diffusers stage I;

- Constructive change of tubes in the tube bundles of the terminal and intermediate coolers;

- Changing of the transmission ratio of gear pairs to change the speed of compressor (11230/77500 rpm);

- Replacement of liners and bearings.

Rotor compressors K-250/500 which are in use at the customer must be upgraded. The company has exchange fund.

| machine liners |

musculoskeletal resistant bearing |

drawing 280Í.14ÑÁ / 0450.14ÑÁ; drawing 280Í.13ÑÁ / 1Õ03.13ÑÁ; |

| reducer inserts: |

musculoskeletal resistant bearingbearing |

drawing 353.14ÑÁ / 252.14ÑÁ; drawing 353.13ÑÁ / 252.13ÑÁ1; drawing 353.13ÑÁ1 / 252.13ÑÁ2; |

|

Seal kit |

drawing 280Í.08ÑÁÌ / 1317.08ÑÁÌ; | |

|

kit clutch gear |

drawing Ó04.27ÑÁ / Ó07.27ÑÁ; | |

| gear with a set of gear couplings | ||

Before performing this type of work, a technical audit of the condition of compressors carries out, to determine the complete list of works at a customer.

Installation supervision, commissioning, technical guidance and participation in acceptance testing of the supplied equipment are carrying out by supervisory personnel of NE "Energomash" Co. Ltd While normal operation of the compressor, there is no need for medium and major overhauls in the next 3-5 years.

printable

printable Home page